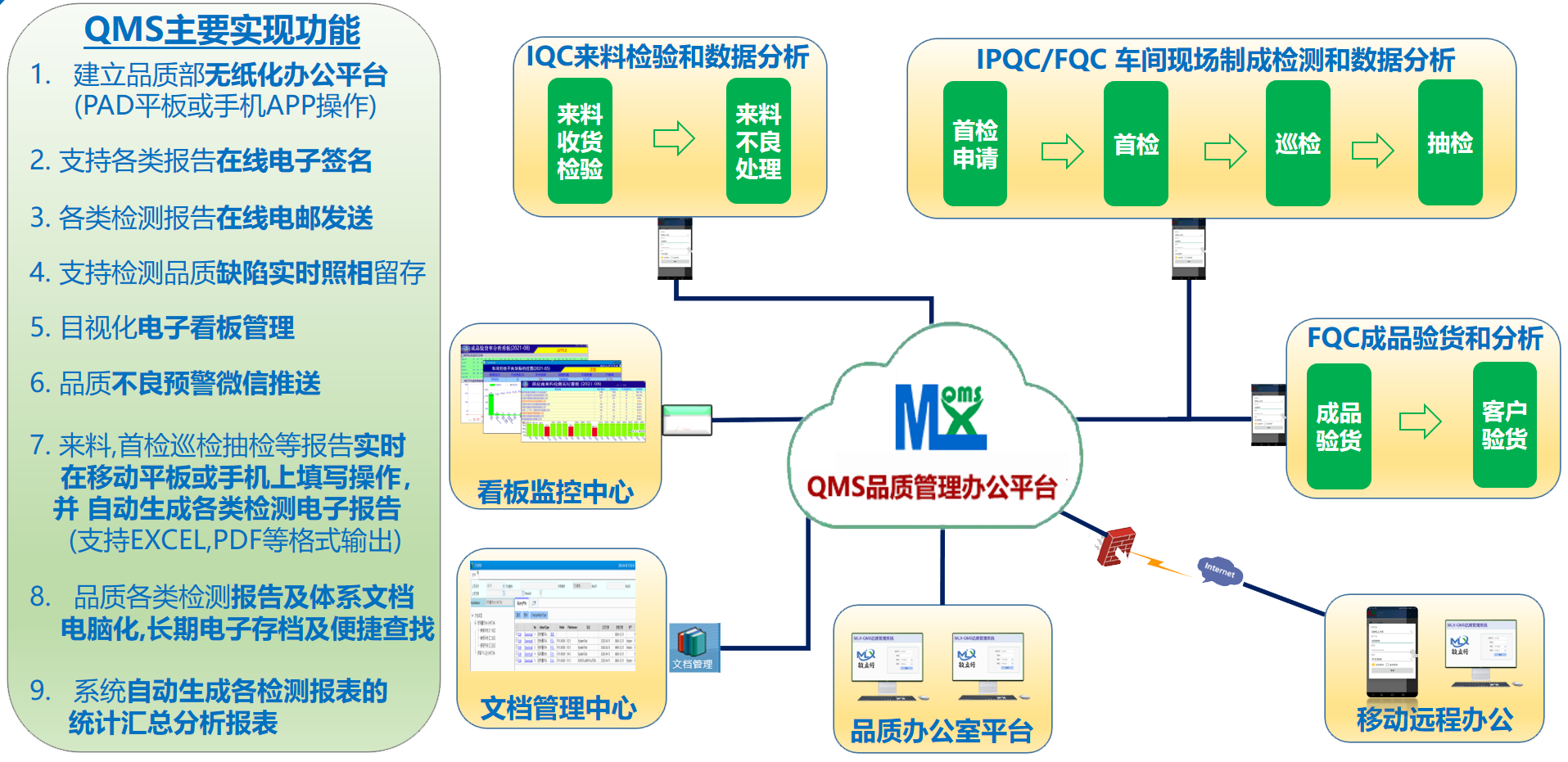

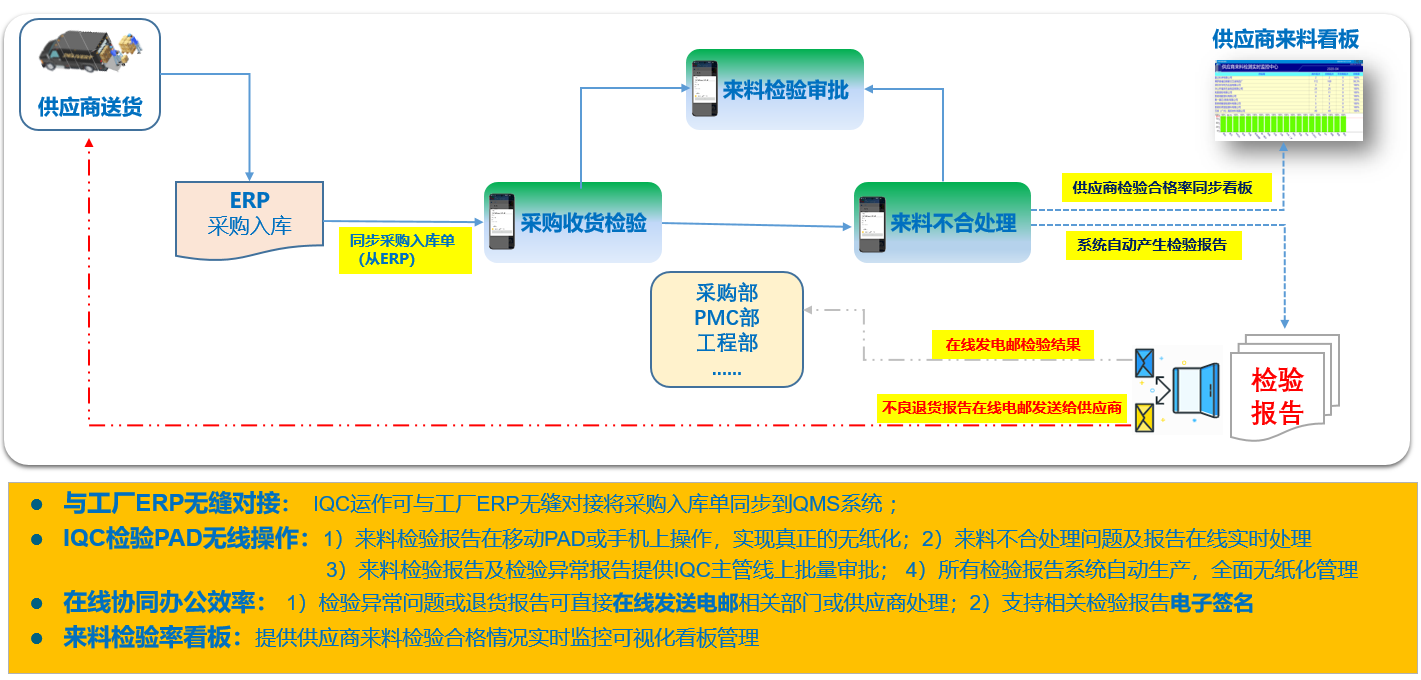

IQC Incoming Material Management

IQC external purchased materials are inspected and filled in on mobile tablets or phones, automatically generating relevant reports, and can email relevant personnel or suppliers

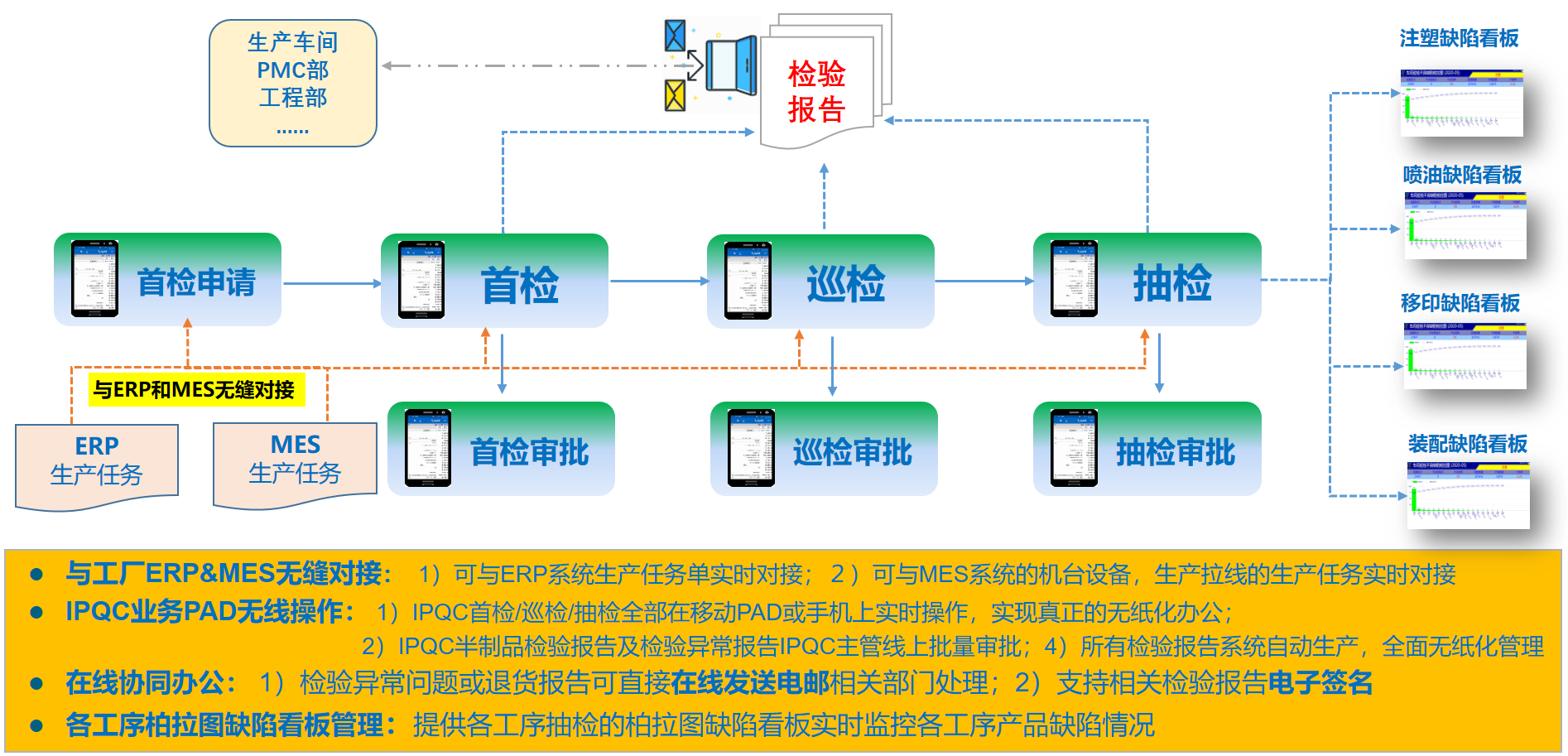

IPQC First Inspection

IPQC fills in the first inspection results of each process online on mobile tablets or phones, and the system automatically generates relevant analysis reports

IPQC Patrol Inspection

IPQC regularly checks the patrol inspection results of each product online on mobile tablets or phones, and the system automatically generates relevant analysis reports

FQC Sampling Inspection

FQC fills in the sampling inspection results of each process online on mobile tablets or phones, and the system automatically generates relevant analysis reports

OQC Finished Product Shipment

Finished product QC, according to PMC or workshop daily inspection of finished product shipments, fills in the inspection results online on mobile tablets and phones, and the inspection results are pushed in real time to the inspection kanban

Email Push / Electronic Signature

Relevant system reports of MLX-QMS can be electronically signed and emailed directly by department personnel, improving work efficiency and establishing a paperless office platform for the quality department

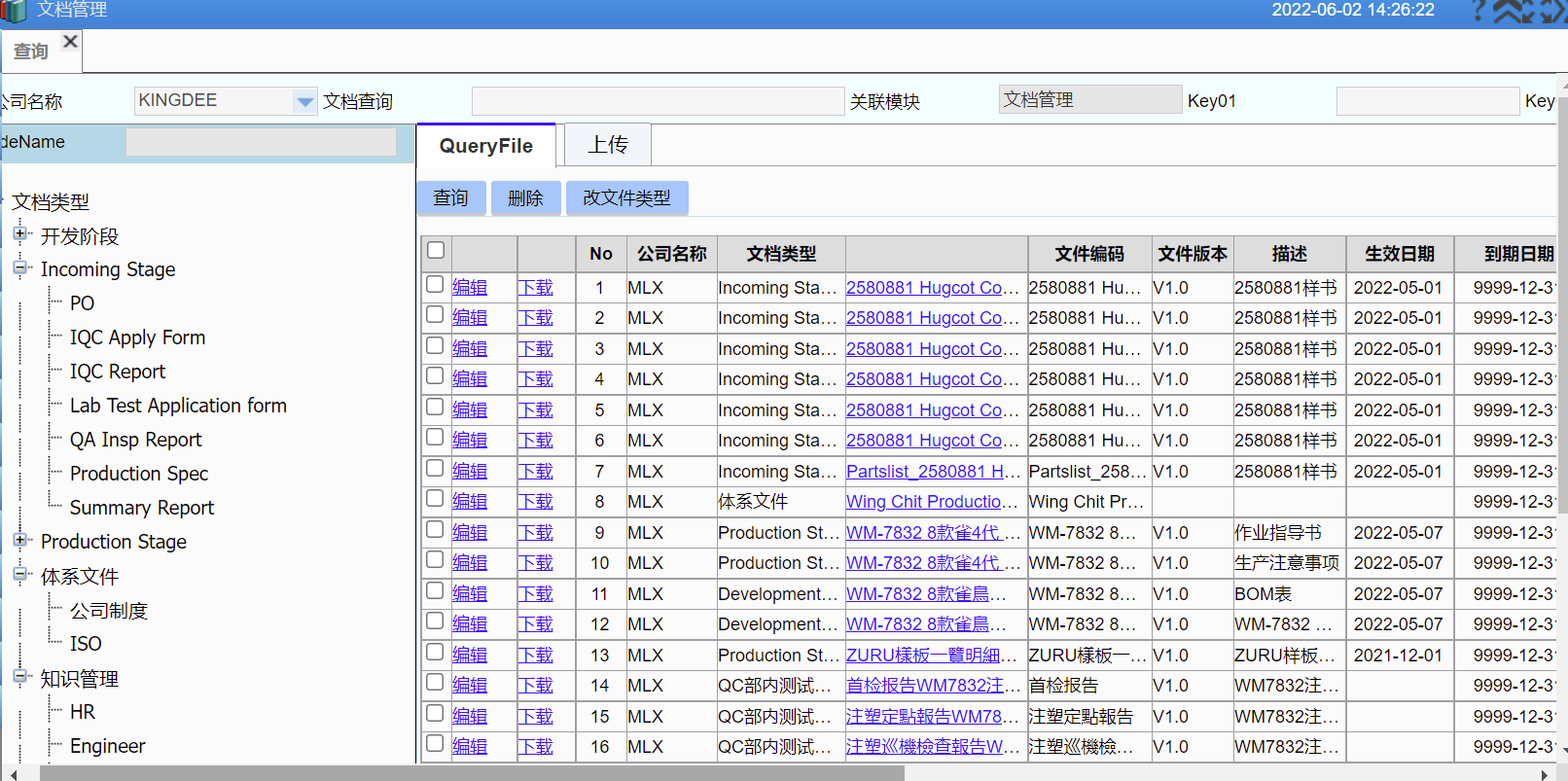

Document Management

The MLX-QMS system platform manages the quality department's system documents, product production-related documents, customer documents, and various department inspection reports, which can be versioned, managed by customer, and associated with related product names and series for easy query and storage management

Electronic Kanban

The quality department's processes are now managed in real time with visual electronic kanban